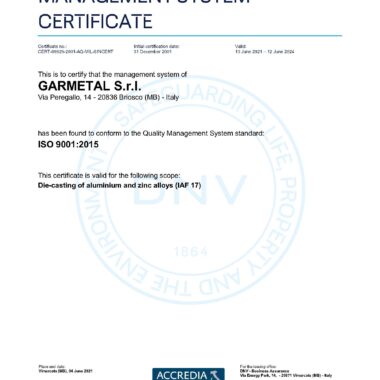

The business management is regulated by a Quality Manual certified to UNI EN ISO 9001:2015

The die-casting process is checked by I.C.S. which controls, at every injection, the stated parameters and

in case of “out of tolerance” rejects the piece in real time.

Visual controls or controls with gages P-NP are made directly during production by our staff;

complex qualitative feature are checked under a microscope.

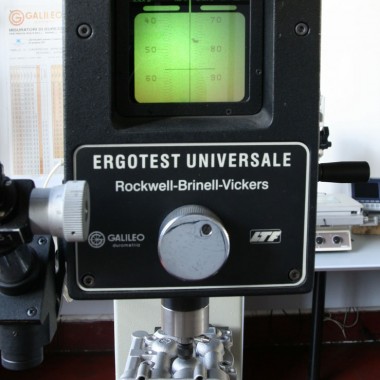

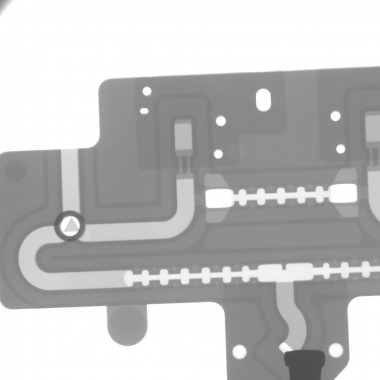

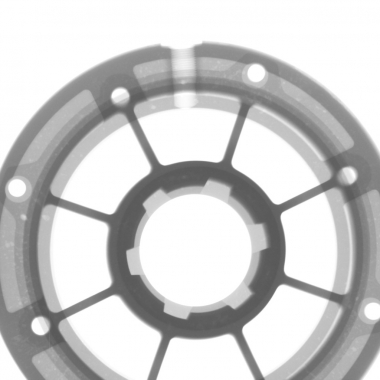

The Quality Department has at its disposal the following instruments: radioscopy system, 3D Optical measuring machine, Surface Roughness measuring machine, Hardness testing machine, digital Altimeter, digital Micrometers all connected to a microprocessor for statistical analysis; Metallographic Cut-off machine, Microscope.

For pressure tests we make use of penetrating liquids and specific “dedicated” devices.

Italiano

Italiano English

English